A chainsaw manual provides essential safety guidelines, operational instructions, and maintenance tips to ensure safe and effective chainsaw use. It covers key aspects of handling chainsaws, including pre-operation checks, proper cutting techniques, and troubleshooting common issues. Reading the manual thoroughly is crucial for understanding the specific features of your chainsaw model and maximizing its performance while minimizing risks. Always refer to the manual before operating your chainsaw to ensure you follow the manufacturer’s recommendations for optimal safety and efficiency.

1.1 Importance of Reading the Manual

Reading the chainsaw manual is crucial for safe and effective operation. It provides detailed safety guidelines, operational instructions, and maintenance tips specific to your model. Understanding proper techniques and hazard avoidance reduces injury risks. The manual also outlines manufacturer recommendations for optimal performance and longevity. Familiarizing yourself with the content ensures compliance with safety standards and helps prevent accidents. Neglecting to read the manual can lead to improper use, potentially causing serious harm or equipment damage. Always prioritize reviewing the manual before operating your chainsaw.

1.2 Overview of Key Sections in a Chainsaw Manual

A chainsaw manual typically includes sections on safety guidelines, operational instructions, and maintenance tips. Key areas cover pre-operation checks, such as inspecting fuel lines and chain tension, and essential safety precautions like wearing protective gear. The manual also details proper cutting techniques, troubleshooting common issues, and storage methods. Additionally, it provides information on environmental and safety regulations, ensuring compliance with local laws. Each section is designed to help users understand their chainsaw better, avoid hazards, and maintain the tool effectively for prolonged lifespan and reliability.

Pre-Operational Safety Checks

Pre-operational checks involve inspecting fuel lines, carburetor, and chain tension, ensuring the saw is clean, and verifying all parts are secure and functional before use.

2.1 Essential Safety Precautions

Always read the manual and follow safety guidelines to minimize risks. Wear proper PPE, including gloves, safety glasses, and a helmet. Ensure the chainsaw is clean and well-maintained. Check for loose or damaged parts and ensure all safety devices, like the chain brake, are functioning. Avoid operating the saw when fatigued or in unsafe conditions. Keep bystanders at a safe distance and maintain a firm grip on the handles. Never cut overhead or near power lines. Adhere to these precautions to ensure safe and effective chainsaw operation.

2.2 Inspecting Fuel Lines and Carburetor

Regularly inspect fuel lines and the carburetor for leaks, cracks, or damage. Tighten loose connections and replace worn-out components. Clean or replace the air filter to ensure proper airflow. Check the fuel tank for contamination and use the correct fuel-to-oil ratio as specified in the manual. A poorly maintained fuel system can lead to engine issues or safety hazards. Always perform these checks before operation to ensure the chainsaw runs smoothly and safely.

2.3 Ensuring Proper Chain Tension

Proper chain tension is critical for safe and efficient chainsaw operation. Check the chain regularly to ensure it is not too loose or overly tight. A loose chain may detach during use, while an overtightened chain can damage the bar or chain. Tighten the chain according to the manufacturer’s instructions, ensuring it has a slight giveaway when pulled gently. Always recheck tension after refueling or during extended use. Proper tension maintains performance and reduces wear on the chainsaw, ensuring optimal cutting efficiency and safety.

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is crucial for chainsaw safety. Always wear a helmet, goggles, gloves, and steel-toe boots. Ensure proper fit and maintain PPE regularly for optimal protection.

3.1 Required Safety Gear

When operating a chainsaw, essential safety gear includes a helmet with a face shield, goggles, gloves, and steel-toe boots. Hearing protection is also crucial to prevent noise-induced damage. Ensure all gear fits properly and is free from wear. Use chainsaw-specific gloves for better grip and control. Steel-toe boots provide protection from falling debris, while a helmet and face shield guard against kickback and flying particles. Always comply with safety standards and wear the recommended gear to minimize injury risks while sawing.

3.2 Proper Fit and Maintenance of PPE

Ensuring proper fit and maintaining PPE is critical for effective protection. Adjust helmets and goggles to fit securely, and wear gloves snugly to prevent slipping. Regularly clean goggles and face shields to maintain visibility. Inspect PPE for damage, such as cracks or worn padding, and replace as needed. Store gear in a dry, cool place to prevent degradation. Check expiration dates for items like earplugs and replace them as recommended. Proper maintenance and fit ensure PPE functions as intended, providing reliable protection during chainsaw operations.

Chainsaw Maintenance

Regular maintenance is crucial for chainsaw performance and longevity. Check and replace worn parts, ensure proper lubrication, and service the engine and chain regularly to prevent issues.

4.1 Regular Maintenance Tasks

Regular maintenance ensures your chainsaw performs optimally and lasts longer. Tasks include inspecting and cleaning the air filter, checking fuel lines for leaks, and sharpening the chain. Lubricate the chain and bar regularly to reduce friction and wear. Replace worn or damaged parts promptly, such as spark plugs or mufflers, to maintain efficiency. Always refer to your manual for specific maintenance schedules and procedures tailored to your chainsaw model. Proper care extends the life of your tool and enhances safety during operation.

4.2 Sharpening the Chain

Sharpening the chain is essential for maintaining cutting efficiency and safety. Use a round file and guide to ensure consistent angles and depths. Start by sharpening the cutters in a forward direction, then flip the chain to sharpen the other side. Keep the file at the recommended angle specified in your manual. A sharp chain reduces kickback risks and improves performance. Regular sharpening prevents the chain from becoming dull, which can cause unsafe operating conditions. Always inspect the chain for wear and damage after sharpening to ensure optimal functionality.

4.3 Storing the Chainsaw

Proper storage of your chainsaw is crucial for maintaining its performance and longevity. Clean the saw thoroughly, removing dirt and debris from the chain and bar. Store the chainsaw in a dry, well-ventilated area away from direct sunlight and moisture. For extended storage, drain the fuel tank or use a fuel stabilizer to prevent corrosion. Hang the chainsaw securely or place it on a flat surface, ensuring the chain is protected from damage. Regularly inspect the chain for rust or wear before storing it again.

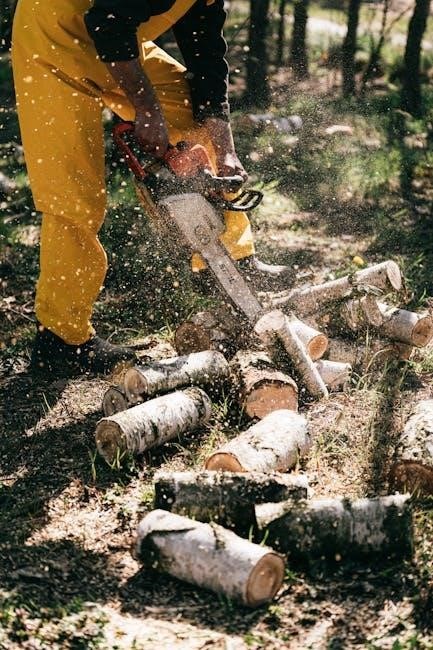

Operating Techniques

Mastering chainsaw operating techniques ensures safe and efficient cutting. Start with basic methods like cross-cutting and limbing, then progress to more advanced felling techniques. Always maintain proper control and balance to achieve precise cuts and minimize fatigue. Practice different cutting angles and positions to handle various materials and situations effectively. Regularly review and refine your skills to improve accuracy and safety while operating the chainsaw.

5.1 Basic Cutting Techniques

Mastering basic cutting techniques is essential for safe and efficient chainsaw use. Start with horizontal cuts for felling trees and vertical cuts for limbing. Always maintain proper control and balance, ensuring the saw is positioned at a comfortable angle. Use a steady, consistent motion to avoid applying too much pressure, which can cause loss of control. Keep the chain sharp to minimize kickback and improve cutting accuracy. Familiarize yourself with the saw’s reaction to different cutting positions and materials. Practice these techniques regularly to build confidence and precision in your cutting skills.

5.2 Cross-Cutting Methods

Cross-cutting involves cutting logs or branches that have already been felled. Start by planning your cuts to avoid obstructions and ensure even distribution of weight. Position the chainsaw at a 45-degree angle to the log, maintaining steady control. Use a smooth, consistent motion to prevent the chain from binding. Keep the chain well-lubricated to minimize friction and improve cutting efficiency. Always stay alert for shifting logs and maintain a safe distance. For larger logs, make smaller, controlled cuts to avoid overloading the saw. Precision and control are key to safe and effective cross-cutting.

5.3 Limbing and Felling Techniques

Limbing involves removing branches from felled trees, while felling focuses on cutting standing trees safely. For limbing, start by cutting smaller branches and work your way up to larger ones to maintain control. When felling, plan the direction carefully, using hinge cuts to guide the tree’s fall. Make precise, controlled cuts to avoid overcutting or creating kickbacks. Always maintain a safe escape route and stay alert for shifting trees or branches. Proper technique ensures efficiency and minimizes risks during both limbing and felling operations.

Troubleshooting Common Issues

Troubleshooting common chainsaw issues requires identifying, diagnosing, and correcting problems such as chain malfunction, engine stalling, or fuel system leaks. Always refer to the manual for detailed solutions.

6.1 Diagnosing Chain Problems

Diagnosing chain issues involves inspecting for wear, damage, or improper tension. Common problems include dull teeth, loose chains, or broken links. Always check for debris or misalignment. If the chain is loose, tighten it according to the manual. Dull chains should be sharpened or replaced. Look for signs of wear, such as uneven cutting or excessive vibration. Proper lubrication is essential to prevent overheating. Regularly cleaning and maintaining the chain ensures optimal performance and safety. Refer to the manual for specific troubleshooting steps and solutions.

6.2 Addressing Engine Issues

Common engine issues include poor starting, rough running, or complete shutdown. Always check the fuel lines and carburetor for blockages or leaks. Ensure the air filter is clean and properly installed. If the engine stalls, inspect the spark plug for fouling or wear. Verify the fuel-to-oil ratio matches the manual’s specifications. Restarting the engine after repairs requires following the manufacturer’s procedure. If problems persist, consult a professional or refer to the troubleshooting section in your chainsaw manual for detailed guidance.

6.3 Solving Fuel-Related Problems

Fuel-related issues, such as poor engine performance or failure to start, often stem from incorrect fuel mixtures or contaminated fuel. Always use the recommended fuel-to-oil ratio specified in the manual. If fuel has been left unused for extended periods, drain and replace it with fresh fuel. Check fuel lines and filters for blockages or damage. If problems persist, inspect the carburetor for proper function and clean or replace it as needed. Proper fuel maintenance ensures optimal engine performance and prevents long-term damage to your chainsaw.

Environmental and Safety Regulations

Compliance with local environmental and safety laws is crucial when operating a chainsaw. Always minimize ecological impact by reducing emissions and properly disposing of waste. Adhere to regulations to prevent harm to the environment and ensure sustainable practices while operating your chainsaw.

7.1 Compliance with Local Laws

Always ensure compliance with local laws and regulations when operating a chainsaw. Familiarize yourself with environmental and safety standards in your area. Many regions have specific rules regarding noise levels, emission standards, and tree-felling permits. Additionally, adhere to workplace safety regulations such as those set by OSHA in the U.S. Properly dispose of waste materials like oil and chain lubricants to minimize ecological impact.

Failure to comply may result in legal penalties or environmental harm. Stay informed and follow all applicable guidelines to ensure responsible chainsaw use.

7.2 Minimizing Environmental Impact

Minimizing environmental impact is crucial when using a chainsaw. Always dispose of waste materials like oil and chain lubricants properly to prevent soil and water contamination. Use eco-friendly alternatives and biodegradable oils when possible. Plan your cuts carefully to avoid unnecessary damage to trees and surrounding vegetation.

Efficient cutting techniques reduce waste, and avoiding over-felling helps preserve ecosystems. Regular maintenance ensures your chainsaw runs efficiently, minimizing emissions and fuel consumption. By adopting environmentally responsible practices, you contribute to sustainable forestry and land management.

This manual emphasizes safety, proper techniques, and regular maintenance to ensure efficient and safe chainsaw operation. It also highlights minimizing environmental impact through responsible practices.

8.1 Final Tips for Safe and Effective Chainsaw Use

Always follow safety guidelines and maintain your chainsaw regularly to ensure optimal performance. Use proper cutting techniques and stay alert to avoid accidents. Wear PPE, including gloves, safety glasses, and hearing protection. Keep the chainsaw sharp and well-lubricated to minimize kickback risks. Plan cuts carefully and consider environmental impact by avoiding unnecessary damage to trees or surrounding areas. Store the chainsaw securely after use to prevent unauthorized access. By adhering to these tips, you can maximize safety and efficiency while using your chainsaw effectively.

8.2 Importance of Continuous Learning

Continuous learning is crucial for mastering chainsaw use, as it enhances safety and efficiency. Stay updated on new techniques, safety standards, and equipment advancements by reviewing updated manuals and participating in training programs. Manufacturers often revise their guidelines, so familiarizing yourself with the latest recommendations ensures compliance and optimal performance. Additionally, learning from experienced operators and attending workshops can refine your skills and adapt to new technologies; By committing to lifelong learning, you maintain proficiency, reduce risks, and achieve better results in various cutting tasks and environments.